That toe jack failure during your critical lift wasn’t bad luck. It was preventable. After 70+ years of manufacturing heavy load moving equipment at Hilman, we’ve seen how proper maintenance dramatically extends equipment life and prevents costly downtime. The most expensive toe jack isn’t the one you maintain regularly—it’s the one that fails during a critical lift.

Key Takeaways

- Preventable Failure Causes: Up to 75% of hydraulic system failures occur due to contaminated or degraded hydraulic fluid, making regular inspection and proper handling essential components of toe jack maintenance.

- Effective Inspection Routine: Regular toe jack inspections should verify smooth stroke operation, structural integrity, pressure maintenance, and absence of hydraulic fluid leakage to prevent unexpected failures.

- Proper Storage Practices: Store toe jacks upright with the ram fully retracted in climate-controlled environments (between -10°F and 140°F) to prevent hydraulic system damage and extend equipment life.

- Safety Protocol Importance: Never use damaged toe jacks for lifting operations, as the risks to personnel safety and equipment damage far outweigh any temporary convenience of continuing work.

- Cost-Effective Maintenance: Proactive toe jack maintenance prevents cascading costs of equipment failure including project delays, emergency replacements, and potential load damage.

The Hidden Causes of Premature Toe Jack Failure

The two most common causes of toe jack failure are improper usage and poor handling. Both are entirely preventable.

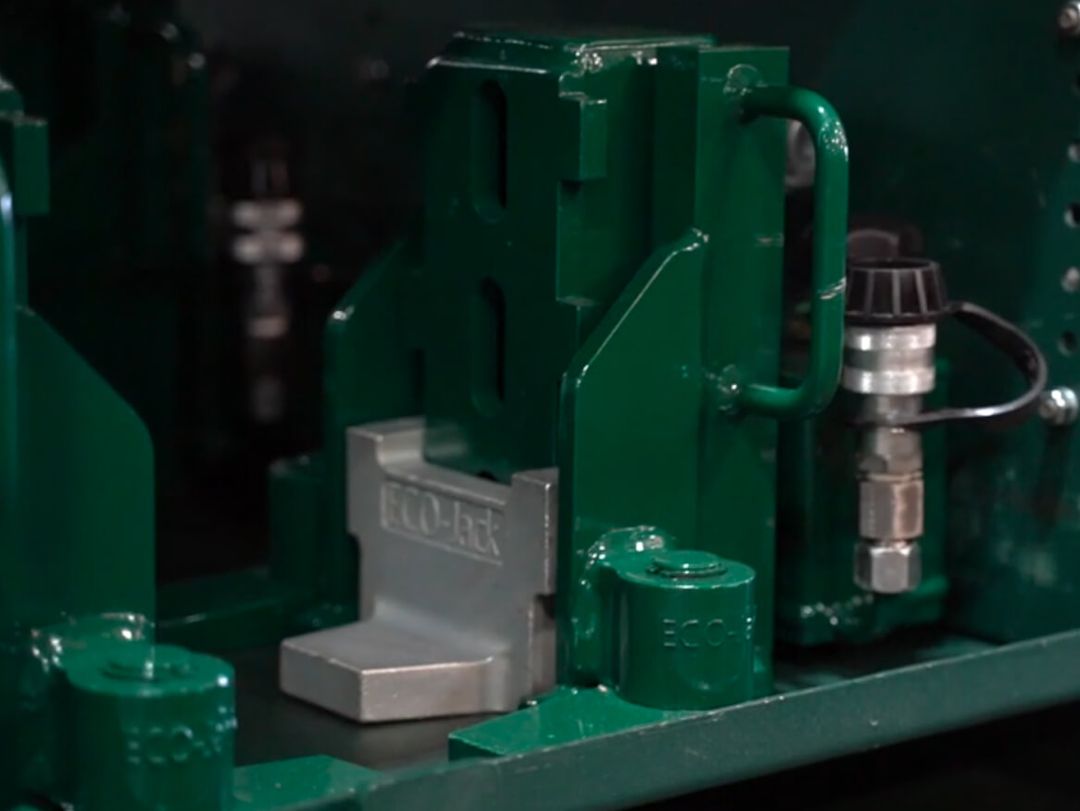

Improper usage includes overloading the jack beyond its rated capacity or failing to use a wedge when lifting. These mistakes can cause catastrophic seal blow-outs in the pump assembly and structural failures in the column.

Poor handling after use is equally damaging. Tossing toe jacks around or storing them improperly damages the pump assembly, release valve, and critical structural components.

Studies show that up to 75% of hydraulic systems fail due to contaminated or degraded hydraulic fluid. This makes regular fluid inspection a critical part of your toe jack maintenance routine.

Your operations team can prevent these failures by establishing proper training protocols and handling procedures. Small changes in behavior create significant improvements in equipment lifespan.

Building an Effective Toe Jack Inspection Routine

Implement a regular inspection schedule based on three factors: usage frequency, environmental conditions, and handling methods.

During each toe jack inspection, verify that your equipment:

- Strokes up to full height smoothly

- Shows no damage to the column or base

- Maintains all capacity labels in legible condition

- Builds and maintains pressure when fully stroked

- Shows no signs of hydraulic fluid leakage

Decommission any toe jack at the first sign of oil leakage. This immediate action prevents further costly damage to internal components.

Remember that toe jacks are precision tools, not indestructible objects. They require careful handling before, during, and after use.

Proper Storage Extends Toe Jack Life

Environmental factors significantly impact toe jack performance and longevity.

Always store toe jacks in an upright position with the ram fully retracted. This simple practice prevents the steel column from exposure to environmental contaminants that lead to corrosion.

Temperature extremes can compromise hydraulic system performance. Hydraulic oil begins to lose stability at temperatures above 140°F and starts to freeze around -10°F. Store your equipment in climate-controlled environments when possible.

Wipe down toe jacks after each use to prevent industrial contaminants from bypassing seals and entering the hydraulic system. Contaminated oil accelerates seal degradation, leading to premature failure.

Chemical exposure presents another risk factor. Acidic substances or fumes can accelerate seal degradation and potentially harm users through skin or eye contact.

Field Failures: When Safety Trumps Convenience

When a toe jack fails in the field, there’s only one correct response: immediate decommissioning.

We strongly recommend against attempting quick fixes or workarounds to complete a job. Almost all toe jack repairs require specialized tooling to address internal component issues safely.

Using a compromised toe jack creates unacceptable risks of injury to users and bystanders, plus potential damage to valuable loads and equipment.

The short-term convenience of continuing work with damaged equipment never outweighs the potential consequences of catastrophic failure. Your safety protocols should clearly state this principle.

Repair or Replace: Making the Right Call

Clear criteria help operations managers make cost-effective decisions about toe jack maintenance.

Replace rather than repair when you observe:

- Physical damage beyond cosmetic scratches to the column

- Heavy scratches or scoring on the column (these will tear through new seals)

- Bending at the base of the column (creates unsafe lifting conditions)

- Cracks in the jack body (compromises structural integrity)

Column replacements and jack body repairs often approach the cost of new equipment. New toe jacks also come with warranty protection, providing additional value.

Factor in downtime costs when making these decisions. Equipment in repair isn’t generating value on your jobsite.

Overlooked Toe Jack Safety Protocols

Our field experience reveals several commonly overlooked safety practices that lead to equipment damage and potential injuries.

These include:

- Overloading jacks beyond rated capacity

- Failing to use wedges during lifting operations

- Using jacks on unstable surfaces

- Improper toe placement under loads

- Poor load center positioning

- Inadequate support at opposite corners (creating tip-over risk)

- Unsynchronized operation when using multiple jacks

Address these gaps through comprehensive training programs and clear visual guides at point-of-use locations. Safety isn’t just about preventing injuries—it’s about protecting your toe jack investment.

The Business Case for Proper Toe Jack Maintenance

Maintenance isn’t just a technical requirement—it’s a business decision with measurable impact on operational efficiency.

Our experience shows that customers who regularly order seal kits and perform preventative maintenance rarely need to send equipment for service. Their toe jacks remain in the field generating value rather than sitting in repair shops.

Less time on the job equals less revenue generated. More time in repair equals higher maintenance costs. The math is simple.

Proactive toe jack maintenance also prevents the cascading costs of equipment failure: project delays, emergency replacement purchases, and potential load damage.

Preparing for Tomorrow’s Maintenance Challenges

Smart operations teams prepare for toe jack maintenance challenges before they arise.

Maintain an inventory of seal kits and repair components for your most critical equipment. This preparation minimizes downtime when issues occur.

Invest in comprehensive training programs that teach proper usage techniques and early problem identification. Every team member should understand what toe jack failure looks like in its earliest stages.

Document your maintenance protocols and create clear decision trees for repair versus replacement. Remove ambiguity from these processes to ensure consistent application.

Remember that your toe jacks are precision tools designed for specific applications. They’re incredibly durable when used correctly, but they’re not invincible.

Consult the Toe Jack Experts at Hilman

The most effective toe jack maintenance program starts with proper use, continues with careful handling, and includes regular inspection. This simple formula maximizes equipment life and protects your operational efficiency.

At Hilman, we’ve spent seven decades engineering solutions that move the world’s heaviest loads. The expertise we’ve built into our equipment extends to how you maintain it. Follow these field-tested toe jack maintenance practices, and your equipment will deliver reliable performance when you need it most.